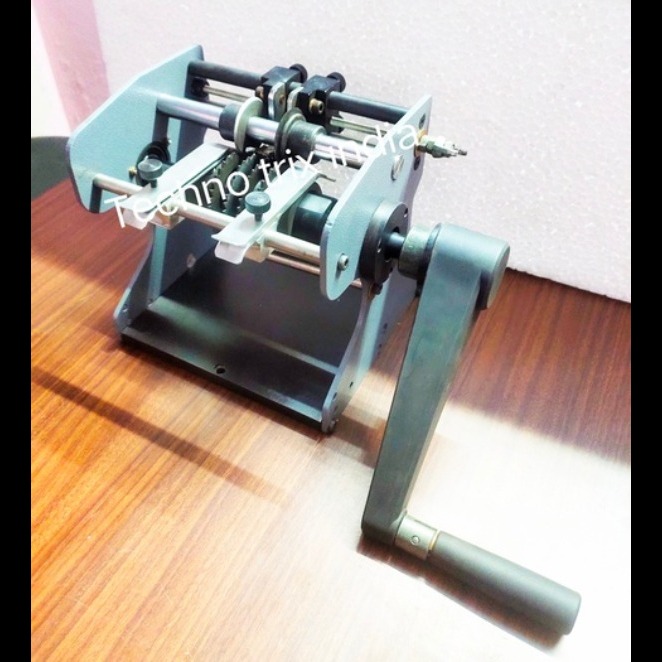

A resistor cutting and bending machine is used in the electronics industry to prepare resistors (and sometimes diodes or axial components) for insertion into PCBs. These machines cut the leads of resistors to a desired length and bend them in specific shapes so they can be easily mounted. 🔧 Types of Machines Manual Machines Hand-operated, low-cost. Suitable for small-scale production or prototyping. Adjustable for lead length and bend angle. Semi-Automatic Machines Motor-driven with manual feeding of components. Higher speed and consistency compared to manual machines. Used in medium production setups. Fully Automatic Machines Hopper-fed or reel-fed system. Automatically cuts, bends, and aligns resistors. Suitable for high-volume production lines. Can integrate with pick-and-place or insertion lines. ⚙️ Common Bending Styles Inline bend (straight-line, 0°) → leads stay straight for vertical mounting. U-bend (180°) → for horizontal mounting on PCB. Box bend (90° each side) → for vertical insertion with resistor body above the board. ✅ Benefits Increases production efficiency. Ensures uniformity and accuracy of lead length & bend. Reduces manual labor and errors. Improves soldering quality during PCB assembly.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry