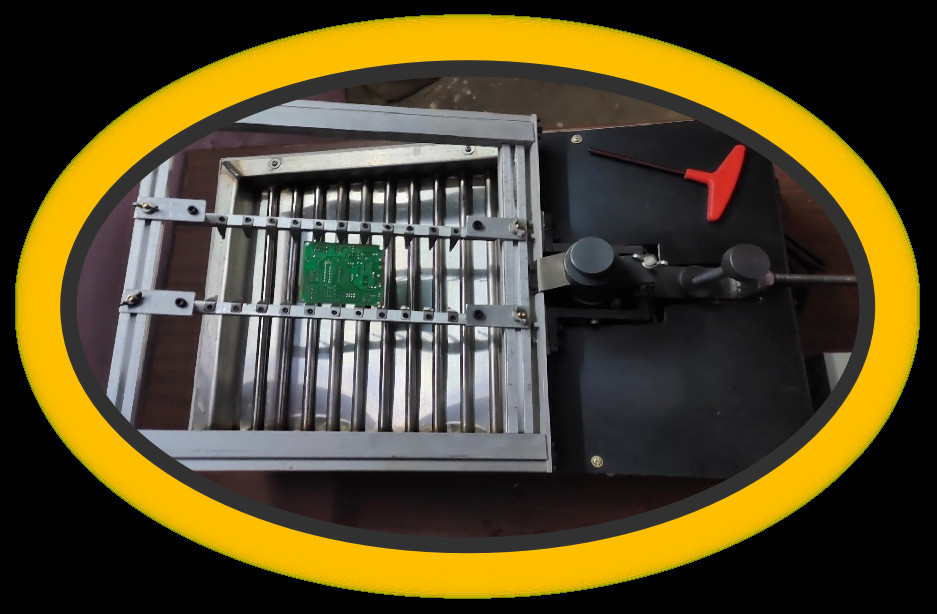

Automatic Dip Soldering Machine Manufacturer in delhi Automatic dip soldering machines are specialized equipment used in electronics manufacturing to efficiently solder components to printed circuit boards (PCBs). Here are some key features and benefits of these machines. Key Features 1. Automated Operation: These machines automate the soldering process, reducing the need for manual intervention and increasing throughput. 2. Consistent Quality: They provide uniform solder application, ensuring consistent quality across all solder joints. 3. Adjustable Parameters: Operators can typically adjust parameters such as temperature, dip time, and solder flow to accommodate different components and board designs. 4. Integrated Flux Application: Many models include systems for applying flux before the dip soldering process, enhancing solder adhesion. 5. Temperature Control: Precise temperature control helps prevent damage to sensitive components. 6. Conveyor System: Most machines include a conveyor system for continuous processing, allowing for high-volume production. Benefits • Increased Efficiency: Automating the dip soldering process reduces labor costs and speeds up production times. • Improved Reliability: Consistent soldering reduces the risk of defects, leading to higher reliability in finished products. • Flexibility: Many machines can handle a variety of PCB sizes and component types, making them suitable for different applications. Applications Automatic dip soldering machines are commonly used in industries such as: • Consumer electronics • Automotive electronics • Telecommunications • Industrial equipment If you’re looking for a specific model or manufacturer, please let me know, and I can provide more tailored information.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Automatic Dip Soldering Machine Manufacturer in...

2024-11-02T05:28:16

Automatic Dip Soldering Machine Manufacturer in delhi Automatic dip soldering machines are specialized equipment used in electronics manufacturing to efficiently solder components to printed circuit boards (PCBs). Here are some key features and benefits of these machines. Key Features 1. Automated Operation: These machines automate the soldering process, reducing the need for manual intervention and increasing throughput. 2. Consistent Quality: They provide uniform solder application, ensuring consistent quality across all solder joints. 3. Adjustable Parameters: Operators can typically adjust parameters such as temperature, dip time, and solder flow to accommodate different components and board designs. 4. Integrated Flux Application: Many models include systems for applying flux before the dip soldering process, enhancing solder adhesion. 5. Temperature Control: Precise temperature control helps prevent damage to sensitive components. 6. Conveyor System: Most machines include a conveyor system for continuous processing, allowing for high-volume production. Benefits • Increased Efficiency: Automating the dip soldering process reduces labor costs and speeds up production times. • Improved Reliability: Consistent soldering reduces the risk of defects, leading to higher reliability in finished products. • Flexibility: Many machines can handle a variety of PCB sizes and component types, making them suitable for different applications. Applications Automatic dip soldering machines are commonly used in industries such as: • Consumer electronics • Automotive electronics • Telecommunications • Industrial equipment If you’re looking for a specific model or manufacturer, please let me know, and I can provide more tailored information.

2024-11-02T05:28:16

Keywords

- dip time

- PCB sizes

- labor costs

- Many models

- solder flow

- key features

- board designs

- solder joints

- Many machines

- Most machines

- specific model

- circuit boards

- component types

- Conveyor System

- solder adhesion

- production times

- finished products

- higher reliability

- Consistent Quality

- manual intervention

- Automated Operation

- Consumer electronics

- sensitive components

- different components

- tailored information

- Industrial equipment

- Improved Reliability

- Increased Efficiency

- Consistent soldering

- Adjustable Parameters

- continuous processing

- specialized equipment

- dip soldering process

- different applications

- Automotive electronics

- high-volume production

- 5. Temperature Control

- uniform solder application

- Precise temperature control

- Integrated Flux Application

- Automatic dip soldering machines

- Automatic Dip Soldering Machine Manufacturer

Submit Your Enquiry